Rail Baltica is a green field railway project for construction of the new high-speed line from Tallinn through Riga and Kaunas to Poland and branch connection to Vilnius with the overall length of 870 km. Project decided to conduct a centralized turnout procurement, as it would allow to develop a state-of-the-art turnout solution with focus on its operational costs and availability.

Background

Background

During preparation for the procurement, Rail Baltica explored the turnout supplier market to find out which solutions in the design of the turnouts can reduce the operational costs. It was found out that the majority of the turnouts on the market have a detection system, which requires periodic adjustment and has limited options for redundancies hence negatively effects availability of the turnout system. Also, maintenance-free sensors for detection do not find a place in the market, despite the availability of the technology. In addition, it was noticed that interoperability and standardization of turnout solutions is not yet achieved. In particularly, interfaces between turnout and the interlocking system which operates and controls the turnout, heavily dependent on the interlocking system setup and manufacturer. However, the development and the first implementations of the EULYNX standard is a good starting point to solve this problem and initiate further development of the turnout`s detection system.

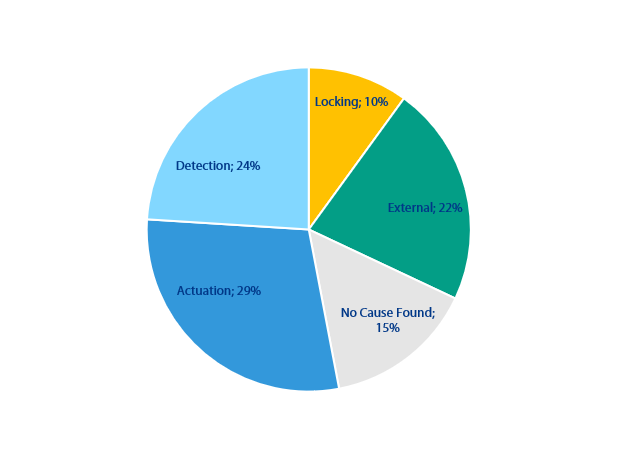

Rail Baltica experts are focused on detection reliability as the latest research as part of In2Rail Deliverable D02.1 – Development of Novel S&C Motion Locking Mechanisms Design Concept Report[1], suggests that the largest causes of turnout failures for existing systems are detection with a score of 24% and actuation with 29%, as indicated in Figure 1.

Considering this, it was decided that the main development in the turnout procurement for Rail Baltica shall focus on detection and actuation to increase the reliability of the turnout system which gives to future Infrastructure Manager a higher availability of the new railway infrastructure. This article will focus only on detection system for Rail Baltica, meanwhile actuation subsystem is planned to be addressed in the separate article.

Problem

Over the years of development of electronic technology, a large number of interlocking systems were developed around Europe. As interlocking systems shall ensure safe train movements according to national operational regulations, its functionality differs from country to country. The architecture of interlocking contributes to this main function of the system. Increasing demand on train traffic triggered the need for development of electronic interlocking systems to allow increase of capacity, reliability, availability, and maintainability of infrastructure. The turnout system being a part of infrastructure connects two large subsystems, namely, railway track (INF subsystem) and control, command and signaling (CCS subsystem). Historically, the turnout system includes track part, actuation, locking, detection, and heating subsystems. Since our focus is on the detection subsystem of the turnout, it was noted that the development of this subsystem depends on the interfaces with interlocking, and it is usually part of interlocking supply scope.

The fact that the scope of interlocking supplier includes detection system, creates a situation where the development of detection solution is limited by interlocking system and interface. This, in its turn, limits the development of the entire turnout system and its subsystems. As the turnout is safety critical system, it complicates further cooperation between the turnout and interlocking suppliers. As a result, the detection system has a design that dates back many decades and is not up to date with today’s state of technology. It also limits development of fully interoperable turnout system with possibility to operate safely in a degraded state using redundancies. This is when some of the rail detectors are faulty, and detection is provided by the remaining detectors without compromising the safety. That degraded operation difficult to achieve with commonly used turnout detection which is based on contacts and microswitches. The one of the reasons is that these detectors provide only “Yes” or “No” status of the target position, and do not have visibility of intermediate status. Also, require periodic adjustment and maintenance, and limits condition monitoring capabilities. However, contactless non-contact detectors with significantly reduced required maintenance are not commonly available on the market. One of the reasons for slow development is the interface between sensors inside detector and logic devices of interlocking.

Expected solution

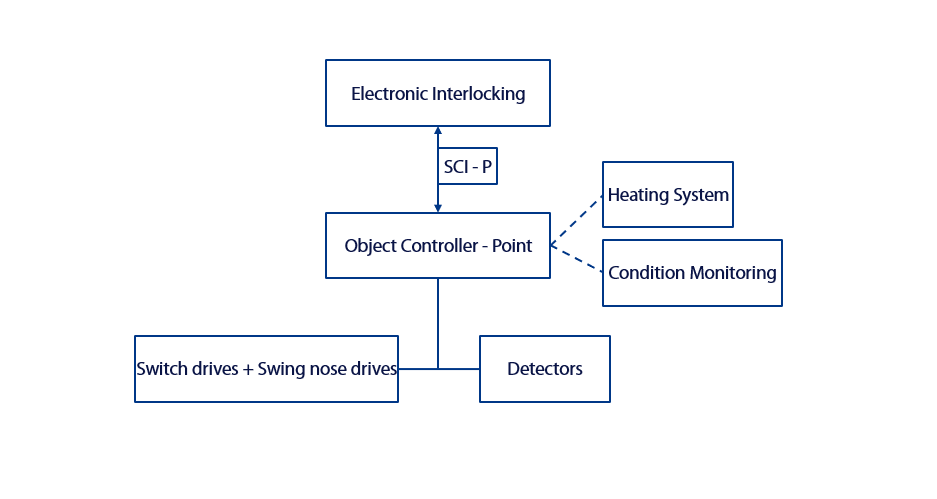

Turnout procurement for Rail Baltica project will try to reduce limitations of the turnout technical solution described above. The scope and responsibilities of turnout supplier and interlocking supplier are defined in a way that it does not limit the development of the turnout system. Schematic diagram below illustrates main subsystems and interfaces of Rail Baltica turnout system and its interface to interlocking. SCI-P interface is a responsibility border between two suppliers.

Since most of the necessary technologies are available and well tested, Rail Baltica aims to have a functioning turnout system within 2 years. As part of this development, not only detection subsystem, but as well track, actuation and heating subsystems are expected to see some improvements using the latest technologies.

Authors: Imants Pizelis, Railway Systems Engineer, RB Rail AS, and Andrejs Mislēvičs, Deputy Head of Systems & Operation Department, RB Rail AS

[1] Development of Novel S&C Motion Locking Mechanisms Design Concept Report: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b36af286&appId=PPGMS